The print is covered by materials which give them new properties. This process allows the product to be distinguished from other competitive offers. This is very important marketing tool because customers “buy with eyes”. It is said that the first impression is the last impression.

We offer a large number of options:

Dispersion varnish can be matt or gloss. It is water-based (ecological) and therefore it is applied to thicker paper sheets. Applying this technique leads to comprehensive gloss and matt effects. Dispersion varnish dries through absorption and evaporation of water.

UV varnish is applied over printed surface and hardened by exposure to UV radiation. It contains reactive resins and strengthening additives. It is used in-line on UV inks and off-line on conventional offset. UV varnish is also used for spot coating.

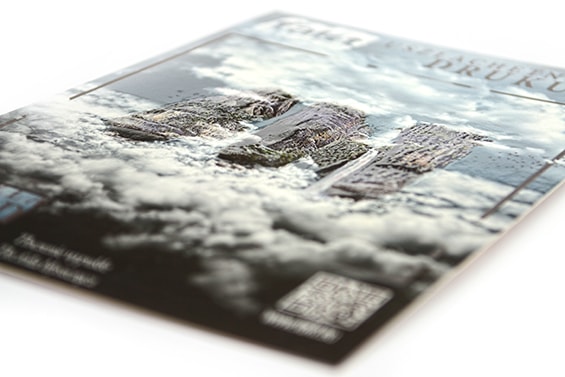

Structural varnish allows to obtain various textures. What is most important, it can cover only selected areas of prints. This varnish does not spill evenly on the surface, but forms densely dotted areas. The effect that can be achieved this way is the effect of sand. The varnish imitates the graininess of the sand and forms a rough coating of the street, a desert landscape, a beach, etc thus giving the printed surface a realistic character.

This varnish increases its volume after printing. This technique gives the possibility to highlight some elements of printing by giving them a spatial effect.

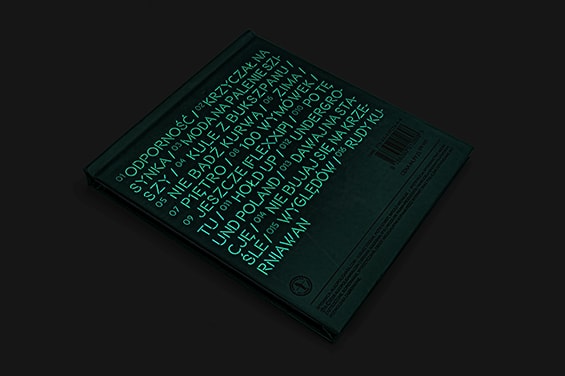

Luminescent paint makes it possible to glow in the dark when exposed to the long-wave ultraviolet frequencies ( UV). Lamination is definitely one of the first and leading methods of printing finishing. It refers to the process of coating the printed surface with a foil. It can be combined with other finishing techniques such as calendering. Printed pieces are laminated to protect them from smudges, stain, moisture, tears etc. Furthermore, print lamination also adds rigidity and strength. You can choose from a whole range of different foils, including glossy, matt, anti scratch, waterproof, metallised, holographic or structural. “Soft-touch” foil is also growing in popularity – by stimulating the sense of touch this finishing method adds a feel often described as “velvety” and “extraordinary”.

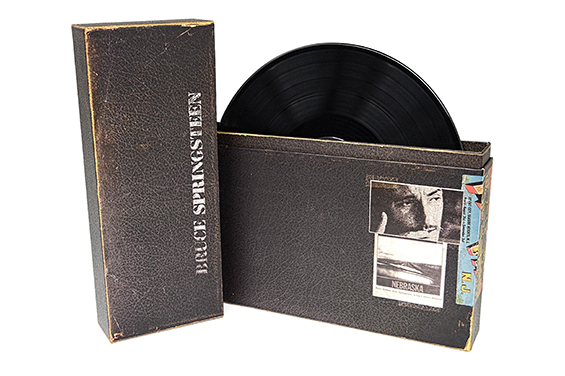

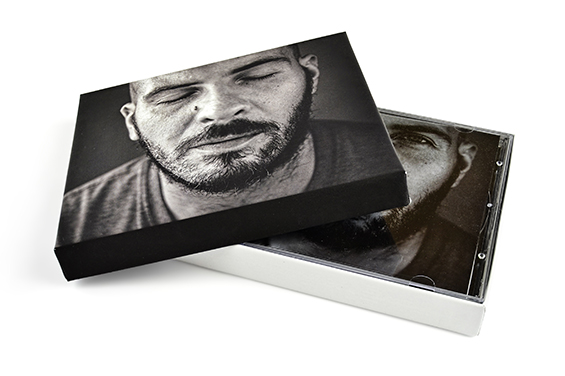

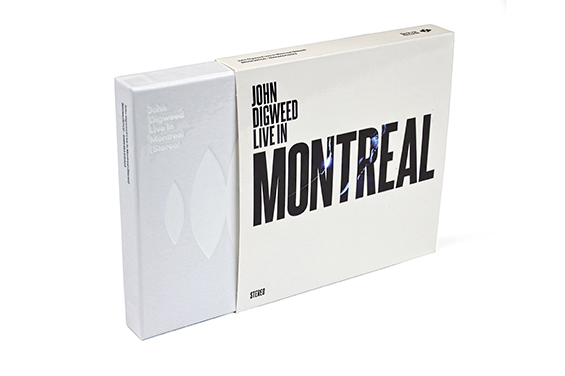

amination is definitely one of the first and leading methods of printing finishing. It refers to the process of coating the printed surface with a foil. It can be combined with other finishing techniques such as calendering. Printed pieces are laminated to protect them from smudges, stain, moisture, tears etc. Furthermore, print lamination also adds rigidity and strength. You can choose from a whole range of different foils, including glossy, matt, anti scratch, waterproof, metallised, holographic or structural. “Soft-touch” foil is also growing in popularity – by stimulating the sense of touch this finishing method adds a feel often described as “velvety” and “extraordinary”.

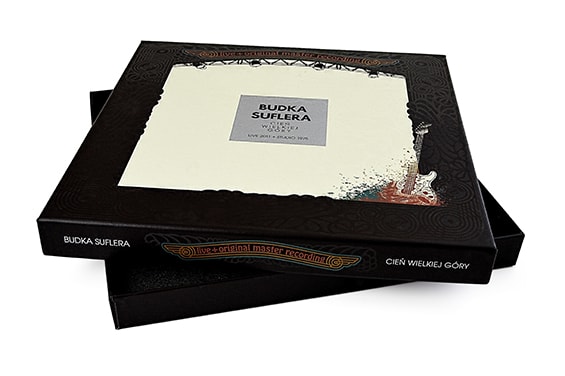

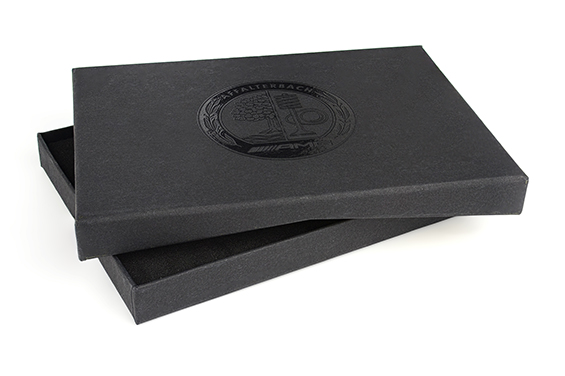

Embossing and debossing are very important finishing techniques used to either impress or depress an image into materials such as paper, cardboard and board . You can have the embossed/ debossed area printed, foil stamped, or leave it blank ( “blind”). Embossing is made using two dies ( personal metal plates ), a “front” and a “back” to slightly raise images off the surface creating this way a 3D effect. Debossing is the opposite of embossing, resulting in dished spatial effects.

A multilevel emboss means the area is raised to multiple levels to create a 3D effect with different depths.

Hot stamping is a method in which metallic foils are transferred to materials such as papers, cardboard, carton, laminated or corrugated board at high temperature. These foils are usually silver or gold, but they also appear in other colors. They can be covered with hologram or rainbow effects. These foils reflect light creating a more eye-catching shiny effect.

Many of the above-mentioned techniques can be combined, which gives you even more opportunities to achieve spectacular results.